Pharmaceutical Blister PVC Rigid Film for Vacuum Forming Cooling Tower Fill

Basic Info

| Model NO. | EYSP20170319001 |

| Density | 1.37g/cm3 |

| MOQ | 500kgs |

| Certificate | ISO9001, ISO14001, SGS |

| Delivery Time | 7-10days |

| Transport Package | Paper Carton+Pallet |

| Specification | 0.2,0.25, 0.35mm or customized as your requirement |

| Trademark | Sea Honest |

| Origin | China |

| HS Code | 3920490090 |

| Production Capacity | 2000tons Per Month |

Product Description

Product Description

| Product Name | Pharmaceutical Blister pvc rigid film for vacuum forming cooling tower fill |

| Application | Pharma Packaging |

| Thickness | 0.25mm,0.35mm or customized |

| Width | Slitted:70-300 mm; Jumbo Roll:500-1600mm |

| Inner Core Diameter | 76mm |

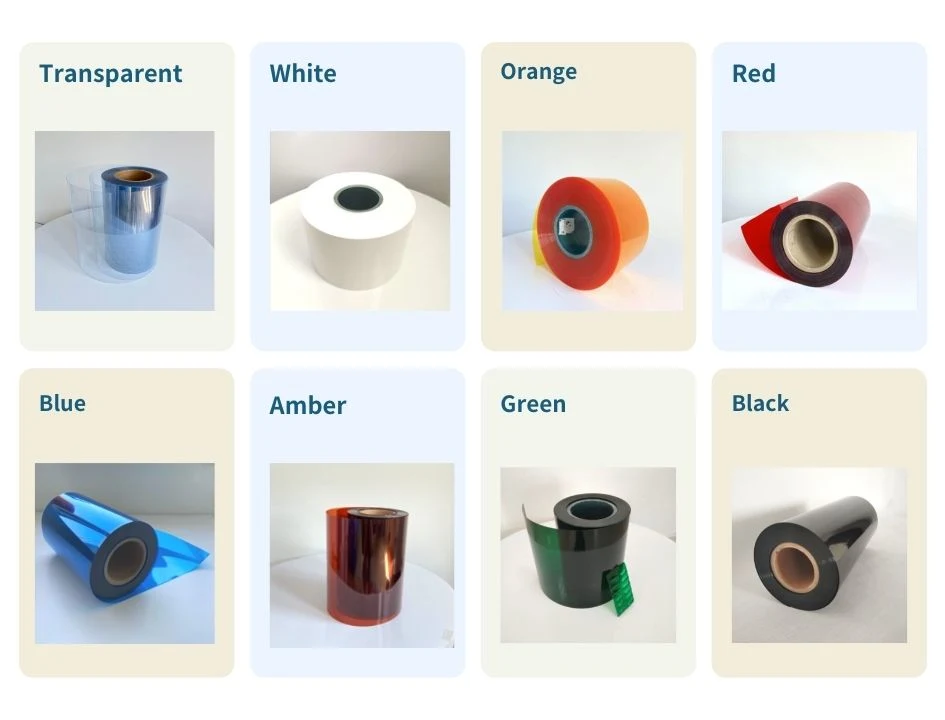

| Color | Transparent, Glass clear,Clear with blue tint, Amber, Orange, White, Blue, Brown, Pink, Green, Yellow or Customized |

| Surface | Bright, Clean and Glossy |

| Delivery time | 7-10 days |

| Advantage | 1.High transparency, bright surface luminance.2.Smooth surface, uniform thickness.3.Few hydrological veins, few crystal points.4.No smell and non-toxic.5.Anti-cold6.Can easily be thermoformed, printed, and folded7.All colors transparency |

| Packaging | In pallet,Paper Carton etc. |

Shandong Enyou New Materials Technology We, Shandong Enyou New material technology was found in 2005. We are located in Zibo city ,Shandong Province. Enyou New material are mainly engaged in manufacturing ,researching and offering plastic packaging films like pharma grade PVC , PVC/PVDC, PVC/PE, alu foil, ptp alu foil, PVC roll/Sheet, PET,PP, PS, shrink film ect, which are widely used in pharma packaging, food packaging, printing ect.Pharma grade PVC, PVDC are one of our advantage products. We have total 18 production lines, 500 workers, most of them have specialized in this field for more than 20 years. And our year capacity could reach 72000 tons per year. Besides, our company have passed ISO9001, ISO4001 ect certificate. Offering customer one stop purchase plan is always our pursuit. And our high quality goods and fast delivery help us win good reputation among our cooperated customers. We have sold our goods to all over the world and our main market are Southeast Asia, South Africa, South America , the Europe ect. If you are interested in our products, please do not hesitate contact us.We looking for build long cooperation with new customers around the world. We promise we will continue offering professional service, high quality products and full solutions of plastic packaging films to you.

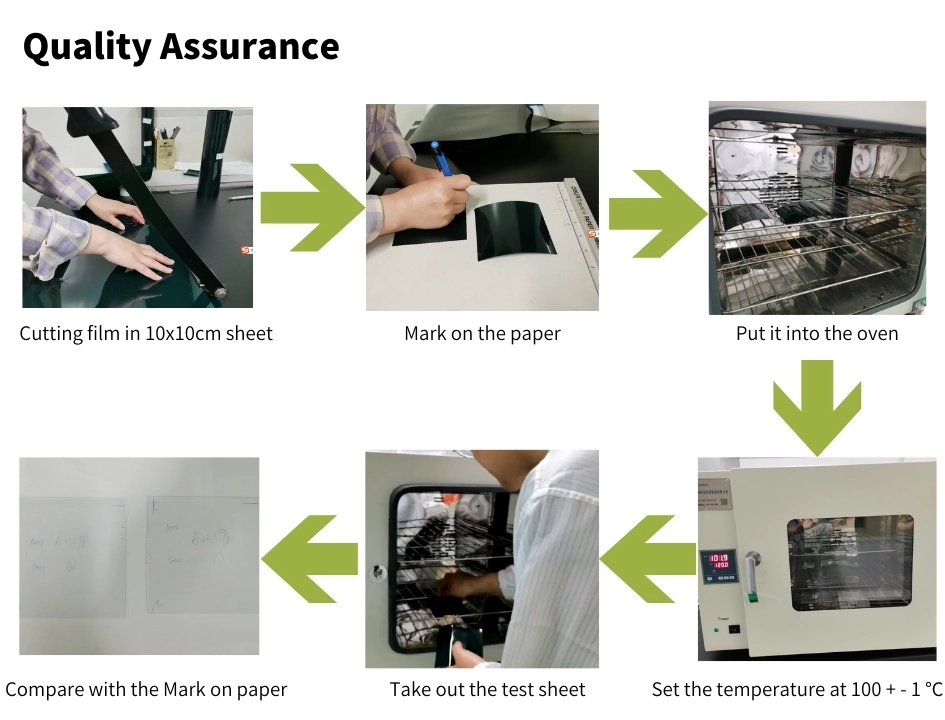

All our workshops are 100000 grade purification workshops, which meet GMP standards. Welcome to visit our factory in the future.Operating procedures for inspection of heating expansion rate1. instruments and toolsBlast drying oven, cutter, ruler2. operating procedures(1) Cut 2 test pieces (100 mm) as specified in Figure 2 from the test piece × Place the test piece on the flat cardboard which can be extended freely and has been preheated, and place it horizontally on 100 mm ± 1 ºC electrothermal blast drying oven.(2) Start timing at the same time, take it out 10 minutes later and cool it to room temperature. Use a ruler to measure the length of AB (longitudinal) and CD (transverse) for original positioning.Explain:1. Oven temperature: national standard oven temperature is 100 ºC, enterprise standard is 120 ºC, higher than national standard2. Shrinkage ratio: National Standard ± 6. Enterprise standard ± fourWe require that the order of the medicine package should not exceed - 3 vertically (the smaller, the later, it will not shrink at last), and + 1.5 horizontally

Packaging & ShippingPVC sheet roll package1.Paper tube Core:76MM2.Paper tube thickness: 10mm3.Paper tube port: No burrs and shredded paper are allowed. It is not allowed to stick with tape. Both ends of the paper tube are flush with the product

Pallet :20tons in 1*20FCLCarton: 22.5tons in 1*20FCLCarton+Pallet:16tons in 20*FCLBulk: 26tons in 1*20FCL

Customer feedback

SHANGHAI CPHI BOOTH NO.: N5A46

FAQ