Plastic Demister C Shape and S Shape Mist Eliminator for Cooling Tower

Basic Info

| Model NO. | BT-PVD |

| Specification | Customized |

| Trademark | BESTN |

| Origin | Pingxiang, China |

| Production Capacity | 1000set/Month |

Product Description

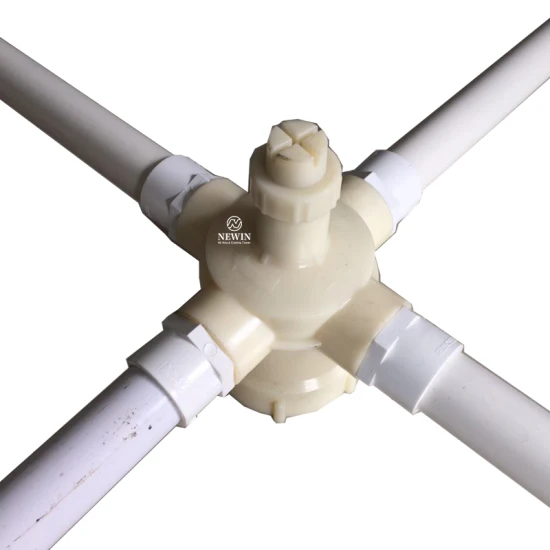

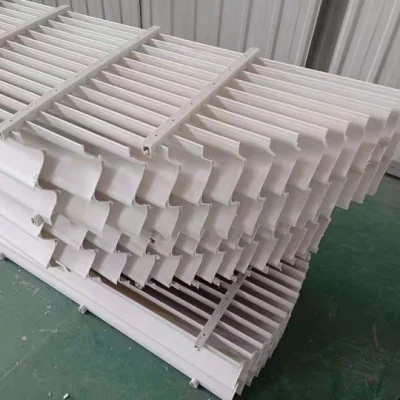

Plastic Demister C shape and S shape PP Mist Eliminator for Cooling TowerEliminator is deducted the hot humid air from the midst of the small droplets drift in cooling Towers, to avoid things around the environment pollution and icy water mist, water saving and environment protection device. Gas flowing at high velocity, when coming in contact with any liquid, carries with itself tiny droplets of the mist. Thisphenomenon is called entrainment. We manufacture demister pads or mist eliminators as they are popularly known that help the process of separating this mist from the gas and provide for the smooth flow of gas .Our demister pads provide a large surface area in a small volume to collect liquid without substantially impeding gas flow. Unlike filters, which hold particles indefinitely, mist eliminators merge fine droplets and allow the liquid to drain away.

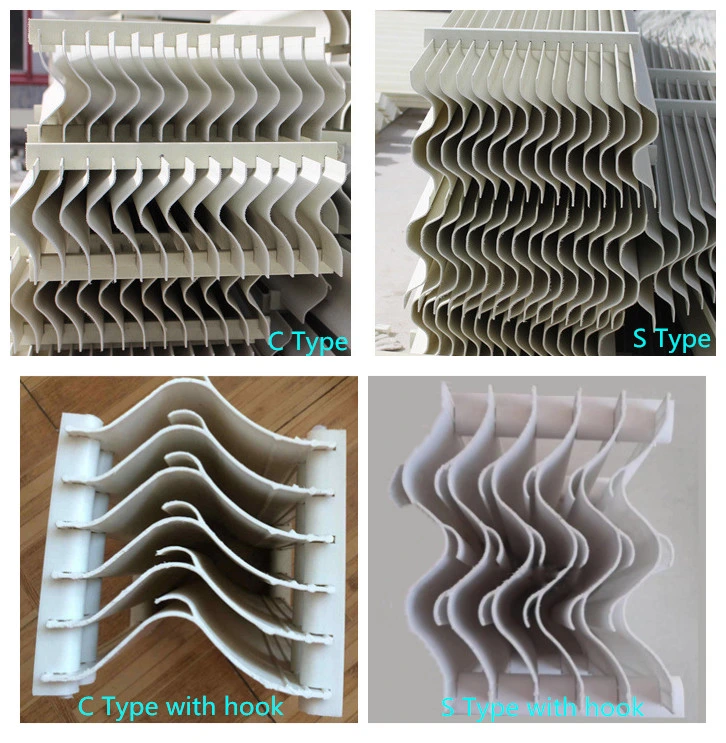

Vane type demister/mist eliminator also known as baffled type mist eliminator/demister is a high capacity inertial separator. Vane mist eliminators consist of closely spaced corrugated plates, which cause the mist-laden gas to change direction several times from inlet to outlet, that force entrained liquid droplets to impinge on the vane surfaces where they form a liquid film and drain. Useable in either vertical (upward) or horizontal flow designs.

Product types

Data Sheet

Items | Technical Data | ||

Material | FRPP | Stainless steel | Fiberglass |

Resistant temperature | 70-80°C | 200°C | 130°C |

Baffle plate thickness | 2.5-3mm | according to customer requirements | Around 2.3mm |

Price performance | Lower | Higher | Higher |

Form | Horizontal type (plate type), Herringbone type (weir type), V type, Combined type, etc. | ||

Area of drift eliminator | The inner diameter of the desulfurization tower area or cross-section area of flue. | ||

Flow velocity of air tower | Plate type 3-4 m/s, weir type 2.5-5.5 m/s. | ||

Degree | Two degrees. | ||

Interval and height between baffle plates | Designed by different desulphurization process. | ||

Flushing layers of flushing systems | Upper and bottom of first-degree drift eliminator, bottom of second-degree drift eliminator, configurable and topper layer of some drift eliminator be flushed in hand. | ||

Amount of droplets discharged by mist eliminator | ≤75mg/Nm3. | ||

1.Excellent defogging effect2.Easy to wash and maintain3.Easy to install4.Low pressure drop 5.Long use life

Product show