Cross Flow PVC Drift Eliminator for Cooling Tower

Cross Flow PVC Drift Eliminator for Cooling TowerNEWIN cooling tower drift eliminators Drift eliminators are designed to

Basic Info

| Model NO. | NBD |

| Tower Shape | Blade or Cellular |

| Noise Level | Low |

| Application Fields | Industrial |

| Certification | ISO, CTI |

| Condition | New |

| Usage | Cooling Tower |

| Application | Replace for Cooling Tower |

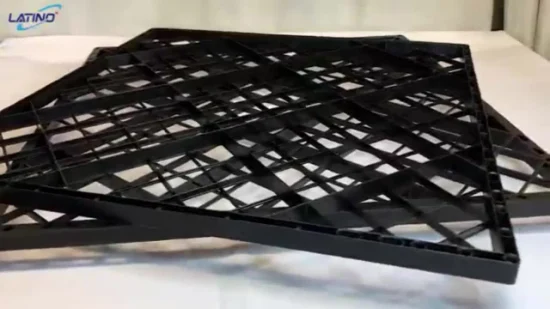

| Transport Package | Wood Packing |

| Specification | CTI |

| Trademark | NEWIN |

| Origin | China |

| HS Code | 8419909000 |

| Production Capacity | 15000 Sets /Year |

Product Description

Cross Flow PVC Drift Eliminator for Cooling TowerNEWIN cooling tower drift eliminators

Drift eliminators are designed to capture large water droplets caught in the cooling tower air stream.The eliminators prevent the water droplets and mist from escaping the cooling tower.Eliminators do this by causing the droplets to change direction and lose velocity at impact on the blade walls and fall back into the tower.

Feaures

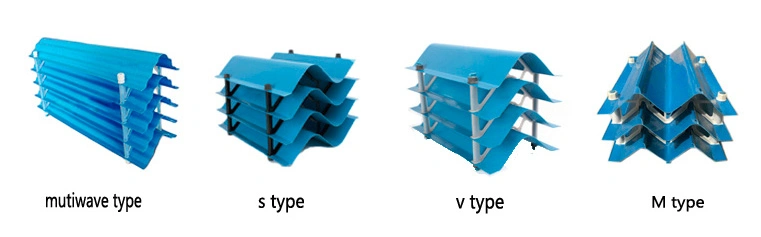

-There are different types, such as V type, S type, M type, mutiwave type and replacement for other brand cooling tower.-Made of flame retardant pvc material.

-Anti-aging, high water absorption, low airflow resistance, high strength, easy installation and long service life.

-Installation with rods and screws.

Specification

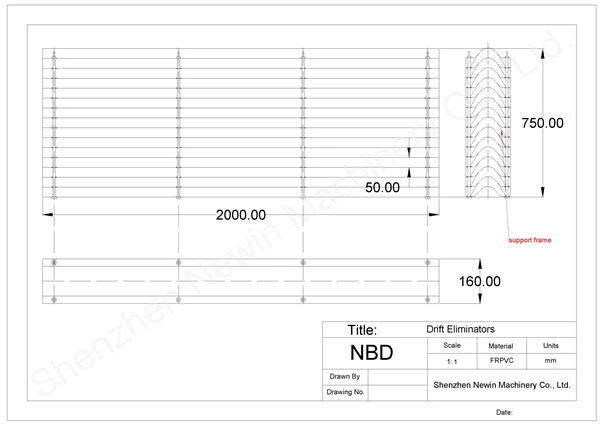

| Model--NVD | PVC |

| Max.length | depend on customer demand |

| Width | depend on customer demand |

| Height | 160/175/220 mm |

| Continuousoperation tempperature | 50ºC |

| Max.applicationtemp.(short term) | 60ºC |

| Color | Black |

| Application | Counter flow & Corss flow cooling tower |

Packing and Loading: LCL shipment: by plywood pallet/case/carton, FCL shipment: by container

Trade Terms: EXW, FOB, CFR,CIF, DDU.

Payment term: T/T, L/C, West UnionMinimum Order Quantity: 1000pcs

Structure DrawingNBD drift eliminator Pictures --- cooling tower drift eliminator Packing & Shipment

PVC Plastic sheet(after molding) Physical and mechanical property

| No. | Item | symbol | unit | index | test method | |

| 1 | density | ρ | g/cm3 | ≤1.55 | GB/T 1033 1-2008 | |

| 2 | tensile strength | lengthways | σt | MPa | ≥42.0 | GB/T 13022-91 |

| crosswise | ≥38.0 | |||||

| 3 | tear strength | lengthways | σtr | kN/m | ≥150 | GB/T 1130-91 |

| crosswise | ≥160 | |||||

| 4 | Folded in half Coldness Resistance Temperature | ordinary type | tb | ºC | ≤-8 | DL/T 742-2001 |

| Frigostabile type | ≤-18 | |||||

| 5 | oxygen index | OI | -- | ≥30 | GB/T 2406 1-2008 | |

GB/T 1033-1986 plastic density and relative density experiment method

GB/T 1040-1992 plastic tensile performance test methods

GB/T 1633-1979 thermoplastic softening point (d) test method

GB/T 1843-1996 plastic cantilever beam impact test method

GB/T 2406-1993 plastic combustion performance test method, oxidation index

GB/T 13022-1991 plastic film tensile performance test methods

GB/T 1190-1991 plastic rectangular tear performance test methods

NEWIN drift eliminator

You may be also interested in below infill/PVC fills/fillings/water filters, please our website:http://newinmachine.en.made-in-china.com for more details.

Contact person

Erin Lian

*******************************************

Website : http://newinmachine.en.made-in-china.com

http://newinmachine.en.made-in-china.com

Send to us